If your dynamic application requires a fast, responsive positioning mechanism that also must fit into a tight space, a direct drive linear motor positioning stage is an excellent choice. After all, linear motor-driven units offer exceptional accuracy and reliability in a compact size. Some of the applications where you’ll find linear motor positioning stages include semiconductor equipment, measuring instruments, assembly systems and material handling machinery. However, many of these applications have an ever-increasing need for high thrust forces and long strokes. This blog post will introduce you to a linear positioning stage that can deliver these and many other in-demand characteristics.

High-Thrust Linear Stages Check Many Boxes

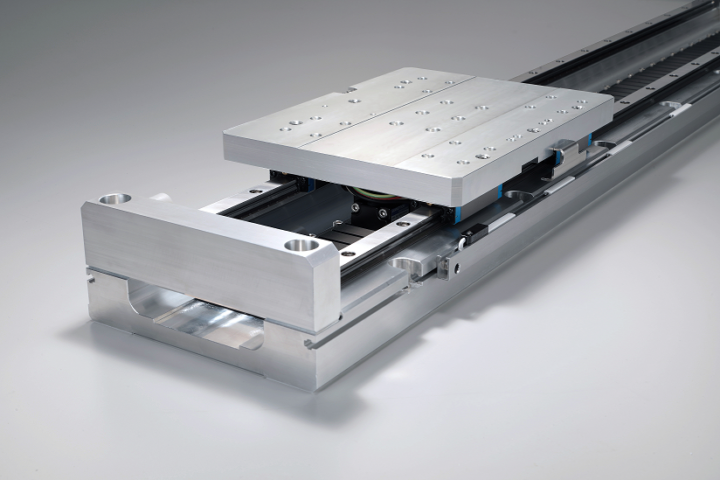

One linear motor positioning stage — IKO’s new LT170H2 — is capable of providing high thrust forces and long stroke lengths while also offering a host of features that designers of semiconductor and other dynamic machines require. This latest addition to the LT family of linear motor stages delivers 260N of rated force and up to 500N maximum, exceeding the thrust ratings of previous LT stages and expanding the linear stage series’ range of suitable applications — especially those that involve positioning heavy objects in constrained spaces.

The integrated linear motor leverages direct drive technology that is free of mechanical power transmission parts that can otherwise hinder positioning accuracy. The LT170H2 also comes with C-Lube linear bearings for guidance. Together, they allow the positioning stage to achieve higher thrusts and high speeds with exceptional precision. Additional features and specifications include:

- High speeds up to 3,000 millimeters per second.

- Repeatable speeds thanks to its low-cogging motor design.

- Reduced cycle times versus the previous LT…H positioning table.

- Long strokes up to 2,750 millimeters.

- Compact size and a 170-millimeter width.

- Low power consumption due to the high thrust rating. In fact, the LT170H2 consumes approximately 48 percent less power than the previous LT…H unit.

The Performance You Need in a Compact Unit

Machine designers no longer have to settle for limited thrust forces and stroke lengths in a compact positioning stage for their dynamic application. Thanks to direct drive linear motor technology that delivers greater thrust forces, IKO’s LT170H2 positioning stages are well-suited for high-speed positioning in constrained spaces. When a machine design calls for a compact positioning stage with higher thrust and longer strokes, IKO’s LT170H2 gives you that option without sacrificing features and performance.

For more information about IKO’s LT Series direct drive linear motor positioning stages, please visit our product page.