During the initial stages of designing a semiconductor manufacturing tool, it’s natural to want to produce a fast proof of concept (POC). And when it comes to integrating a motion component while proving that concept, designers tend to begin with stainless steel parts. In our previous blog post on semiconductor manufacturing, we provided an overview of some of the most common motion products used for cutting-edge applications and the features that make them ideal for this demanding industry. This blog post will explain why it pays to use standard products made from carbon steel early in a design’s development before moving forward with custom stainless steel parts.

Standard Materials Are Practical and Expedient

It’s no secret that stainless steel is fast becoming the material of choice for designers when integrating motion components into semiconductor equipment. However, the benefit of using a stainless steel part early on when developing a device is typically minimal. At this point, the material may not be readily available and the advantages of stainless steel may go unrealized.

For early iterations of a machine design, choosing standard products, such as those made from carbon steel, is often a very practical and expedient approach — especially when you evaluate products from a motion supplier with a broad range of off-the-shelf products and extensive engineering support. Following this logic, IKO’s ML Series linear motion rolling guide, which comes standard in stainless steel, also offers several sizes in carbon steel. High-quality standard carbon steel bearings will provide the performance you need as you begin testing, and IKO can provide a custom-designed stainless steel version at a suitable time, such as when the design concept is in line for prototyping or beta testing.

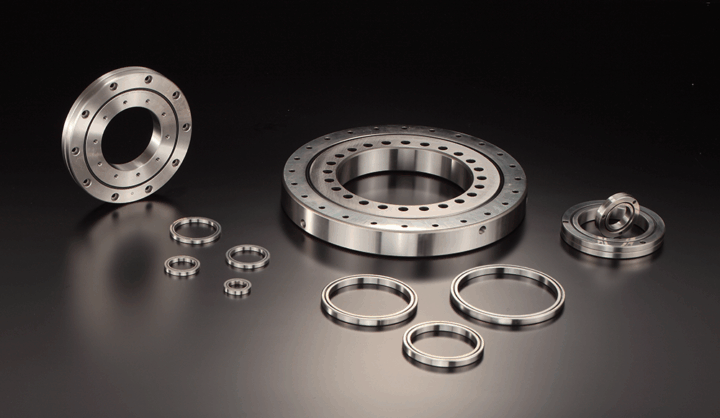

During the POC phase, chances are you will need to start with several parts for trial and error and narrow them down to only a few custom parts. And, those custom parts take months to validate and manufacture. Using standard parts early on reduces the time requirement from months to days or weeks, provides cost savings and doesn’t incur the added expense of stainless steel. And when it’s time to migrate to a custom stainless steel bearing, the optimization steps are faster and easier. Using IKO’s Crossed Roller Bearing Series as an example, preliminary testing with a standard carbon steel CRB, or even a carbon steel CRB with Black Chrome Surface Treatment, will offer a drastic reduction in initial lead time and cost compared to a fully custom stainless steel CRB.

Don’t Let Perfect Be the Enemy of Good During POC

When you choose IKO, you partner with a manufacturer that boasts a broad range of motion products like crossed roller bearings and linear guides. Because a standard bearing will perform well in an initial test environment, we can provide an off-the-shelf carbon steel-material part to help you determine whether the design philosophy is attainable. And when ready, we can provide a custom-designed stainless steel version for prototyping or beta testing. Our sales engineers can help you determine the best standard bearing for your semiconductor manufacturing application.

For more information, please visit www.ikont.com.