In vacuums, standard greases can cause several problems. Vacuum pressure causes vapors to disperse and contaminate sensitive semiconductor manufacturing processes. Higher operating temperatures can have an evaporative effect on the grease that will degrade lubricity. Motion causes grease to wear and emit contaminating particles. These outgassing, wear and evaporative risks pose challenging trade-offs when selecting lubricants for product designs that have demanding performance cycles at long maintenance intervals.

Operating parameters may dictate that a relubrication schedule is in fact required, so checking with your bearing supplier to discuss the trade-offs is recommended. An ideal partner will offer a lubrication recommendation that offers a balance of high durability and low evaporation in vacuum environments while also exhibiting low outgassing and low dust-generating characteristics.

One such lubricant that offers a robust, noncompromising balance of high-performance and superior outgassing characteristics is IKO’s proprietary Liquid Crystal Lubricant (LCL). This new lubricant is not a grease or an oil and has an operating temperature range from 5°C to 100°C, with an instantaneous peak up to 120°C. LCL provides exceptional cleanliness, durability, outgassing, evaporative and frictional resistance characteristics that clearly outperform traditional cleanroom and vacuum greases. IKO’s LCL is now available as a stand-alone product and is also available within IKO’s stainless steel standard lubrication-type linear guide series and IKO’s crossed roller bearing series.

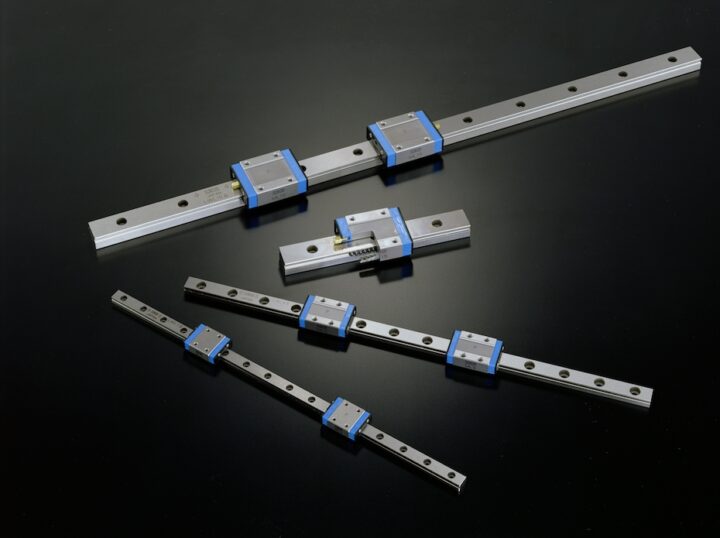

For machines that do not operate in a vacuum, you can achieve smooth, long-term maintenance-free linear motion using IKO’s linear guide series with integrated C-Lube technology. C-Lube is IKO’s proprietary internal lubricating system that utilizes porous oil-impregnated polymer parts within the bearing’s internal recirculation path to provide long-term, maintenance-free operation up to 20,000 km (12,500 miles) or five years.

For example, C-Lube technology is integrated into IKO’s Linear Way ML miniature rolling motion guide. This unit combines stainless steel components and a miniature design footprint, making it especially desirable for clean environments. It also eliminates the hassle of relubrication in enclosed or otherwise difficult-to-access spaces and where downtime is not an option.

Another lubrication option — cleanroom greases — minimize particle generation and rolling resistance. They can be found both in select linear guides built for strict cleanliness requirements or as stand-alone products.

Don’t Forget Packaging

Packaging specifications for cleanroom and vacuum applications are an important consideration that can be overlooked when specifying a part number. Standard rust preventive oils applied to finished bearings before packaging are not compatible with clean or vacuum lubricants and environments. An ideal bearing manufacturer will offer several solutions to simplify or eliminate required processing after receipt, such as a specification that omits the rust preventative oil coating altogether or one that reduces the amount of rust preventative oil applied. At IKO, we offer both of these supplemental specifications and VCI film packaging materials.

For more information, please visit www.ikont.com.