IKO’s MX series of linear roller bearings delivers a combination of extreme rigidity, high accuracy and smooth motion which are all required for demanding applications (such as machine tools, semiconductor manufacturing equipment and liquid crystal manufacturing equipment) or any other applications subject to shock, vibration or overhung loads.

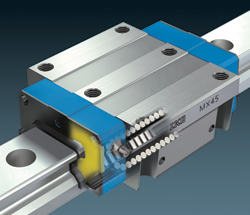

The MX series utilizes four rows of cylindrical rollers which provide a greater contact area and deliver a higher load capacity than slides that use steel balls. Slides with steel balls also have a tendency to deform under high loads, whereas IKO’s MX range offers an extremely rigid guide rail to significantly increase the performance of the machines they are designed into. This lack of deformation ensures extremely stable performance under fluctuating or heavy loads.

The MX series also provides damping to allow the bearings to deliver machining accuracy, high-speed cutting and precision grinding, under high vibration and shock conditions.

IKO’s proprietary C-Lube system for maintenance-free use of bearing systems has been incorporated into the MX series. As the MX cylindrical rollers circulate, the lubricant is distributed to the loading area through the rollers along the track rail. This results in lubrication being properly maintained in the loading area for 20,000km and significantly reduces valuable time spent lubricating hard to reach parts.

In addition, most of the slide units and track rails in IKO’s versatile MX series are fully interchangeable. This provides engineers with greater design freedom and enables parts to be matched, replaced or added freely.